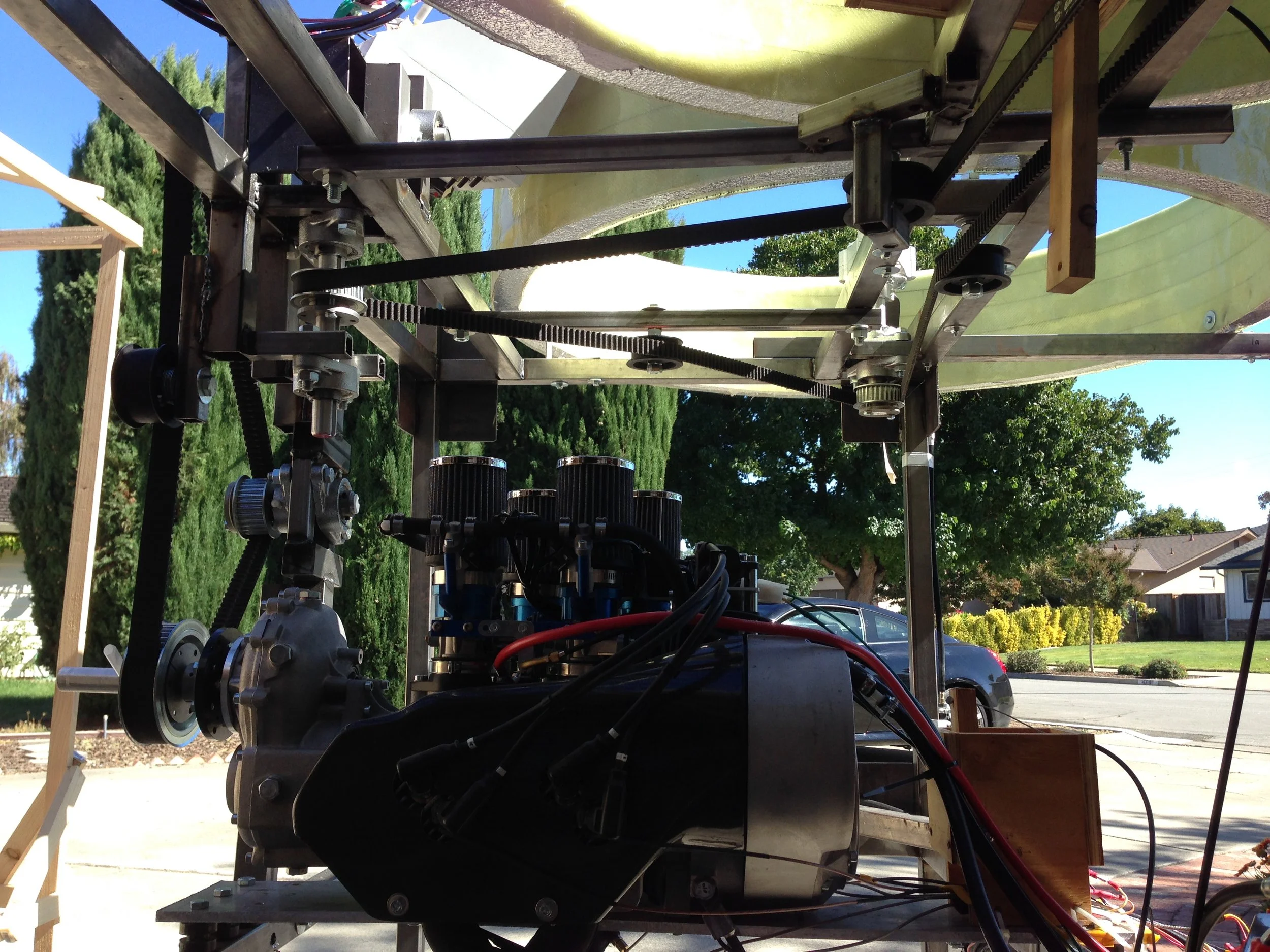

You can imagine we got some fully looks from people driving down the road with this in the back. We were on our way to break in the engine at an airport (it needed to be run at various speeds for ~5 hours)

The propeller is traveling so fast it gets distorted (in reality it's a straight blade)

One of our testing crews

Another testing crew - this time when the Mark I was shredding belts

We got some funny stares when we parked in front of a taqueria for lunch after some testing

I keep one of the shredded belts on my wall as a reminder to never stop pushing forward (and that I'm crazy)

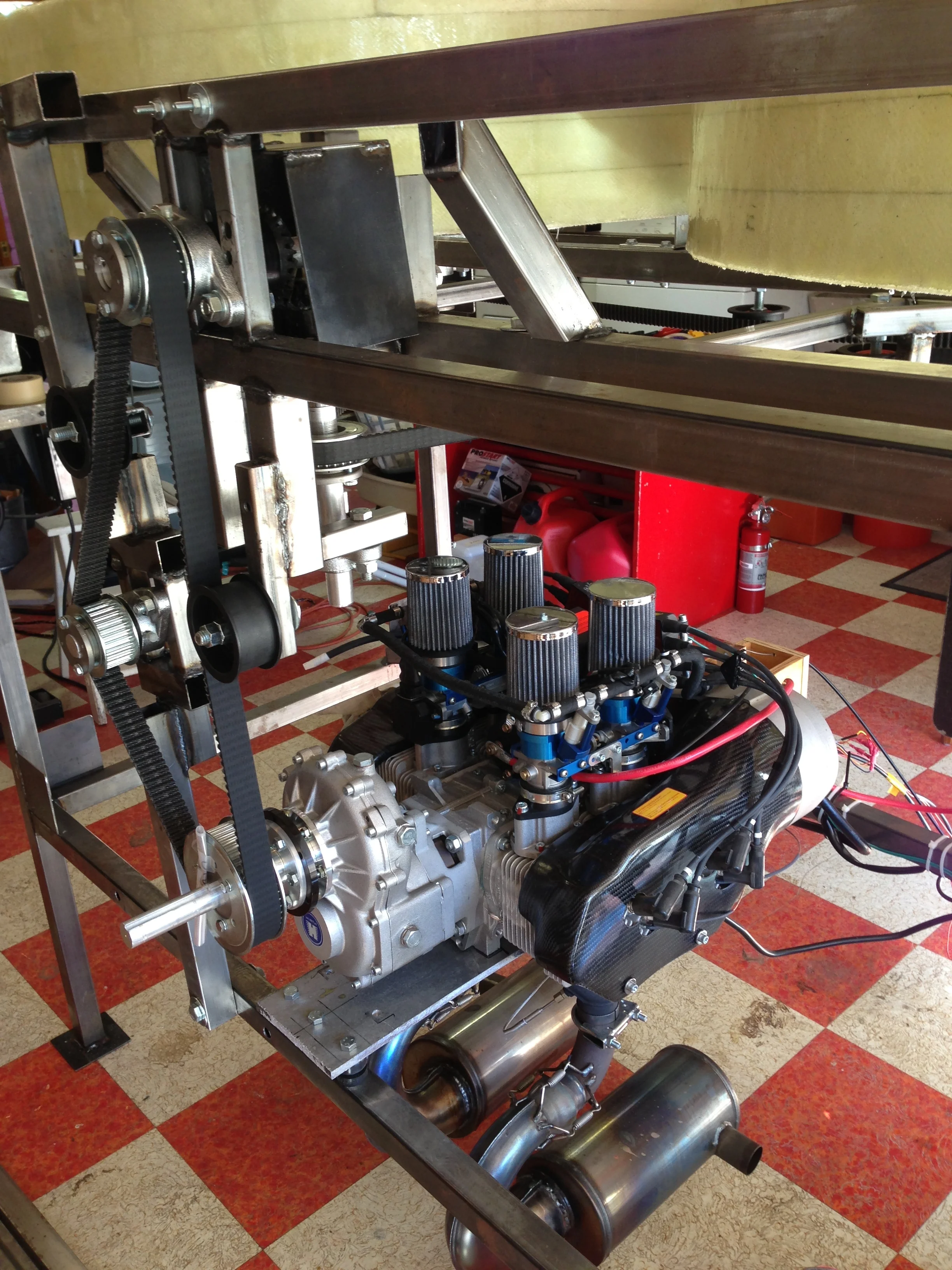

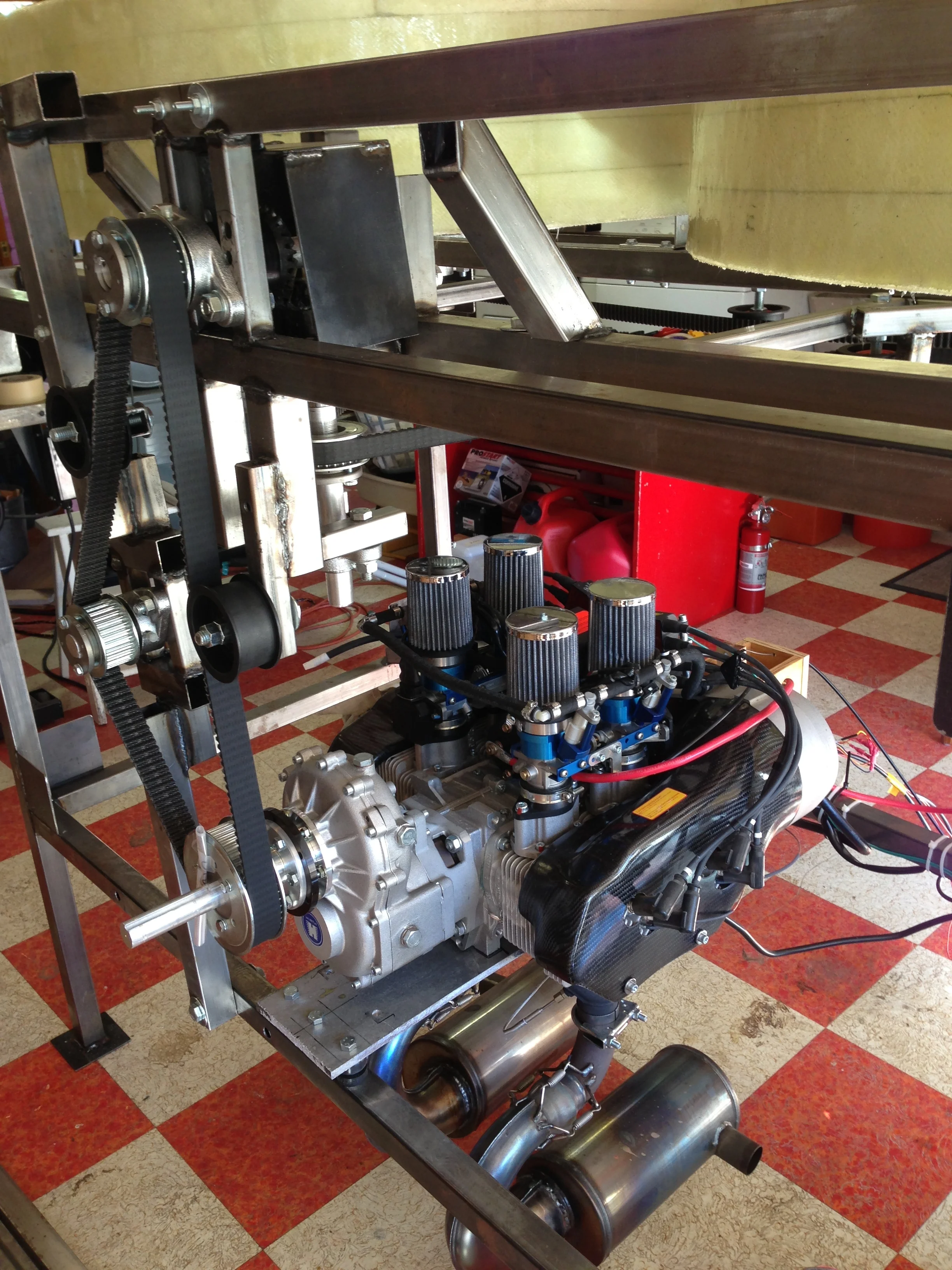

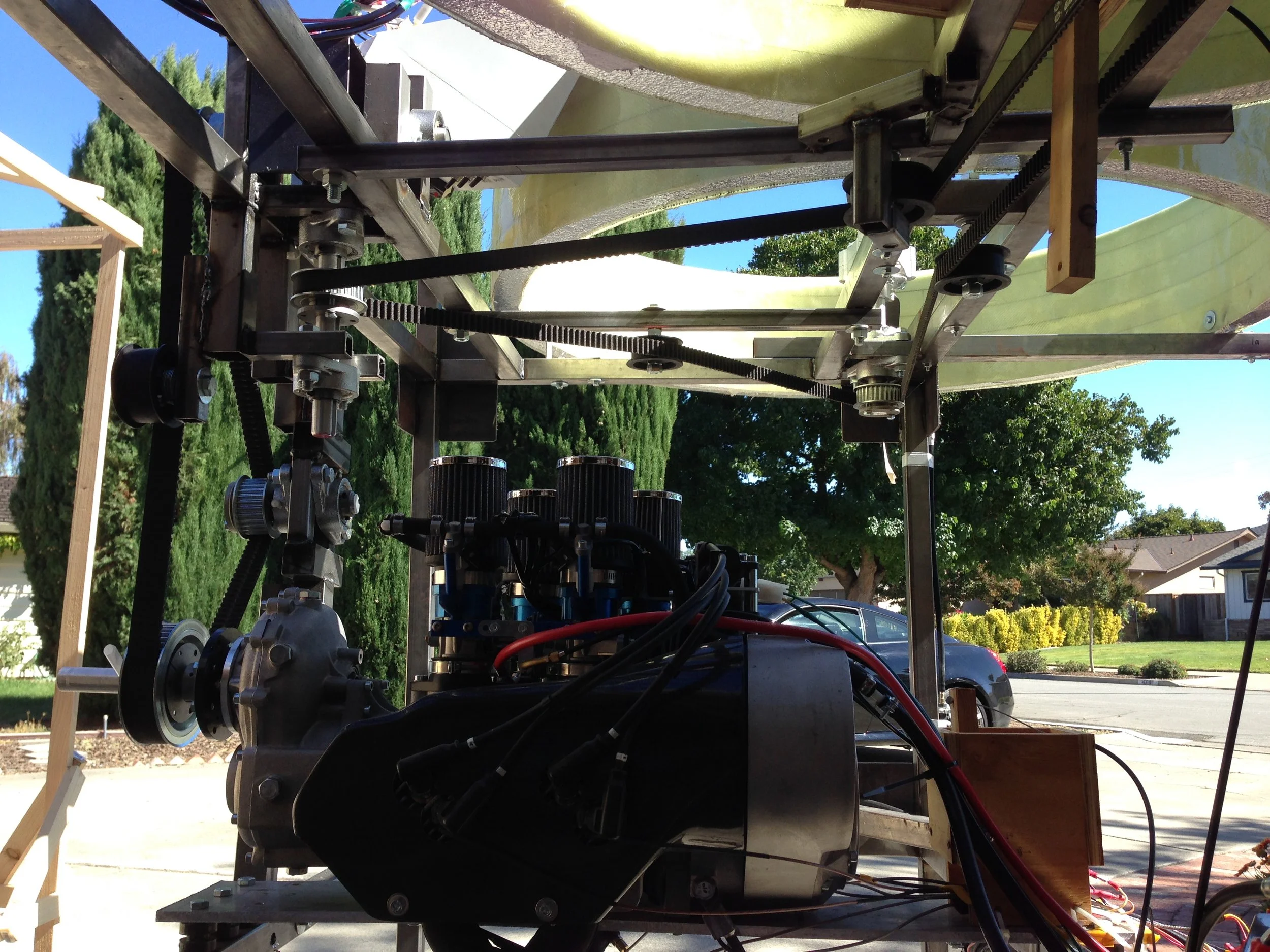

One of the many belt configurations that was tried

This was the remote box we could start/stop the engine, see the tachometer and temperature, as well as control power to the fuel pump and whatnot

First-generation ducts were made from Styrofoam cut with a bandsaw and glued together

Epoxy requires careful measuring

Painting epoxy on the fibergalss cloth to form a duct

The foam duct core only weighed ~1lb - but a 44" propeller is still pretty big!

No one said construction couldn't be fun! Sometimes it's easier to just climb on the thing to make modifications.

If a gear was particularly difficult, we'd freeze the assembly to loosen the Alumnum shaft from the steel bushing

Under load, we frequently broke things and had to re-enforce them. In this case a 1/2" thick bolt bent at 15 degrees and had to be replaced with a stronger steel bar.

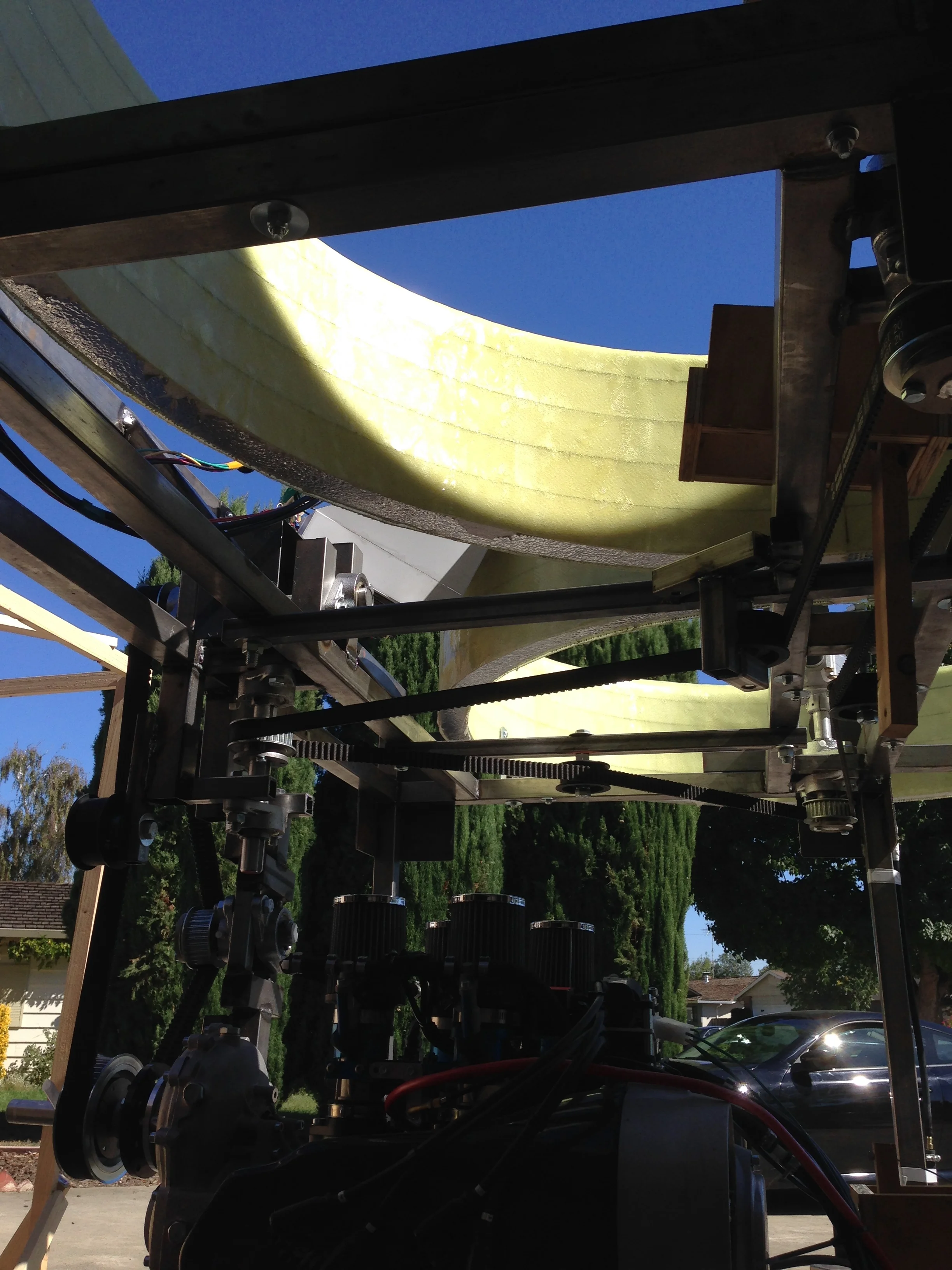

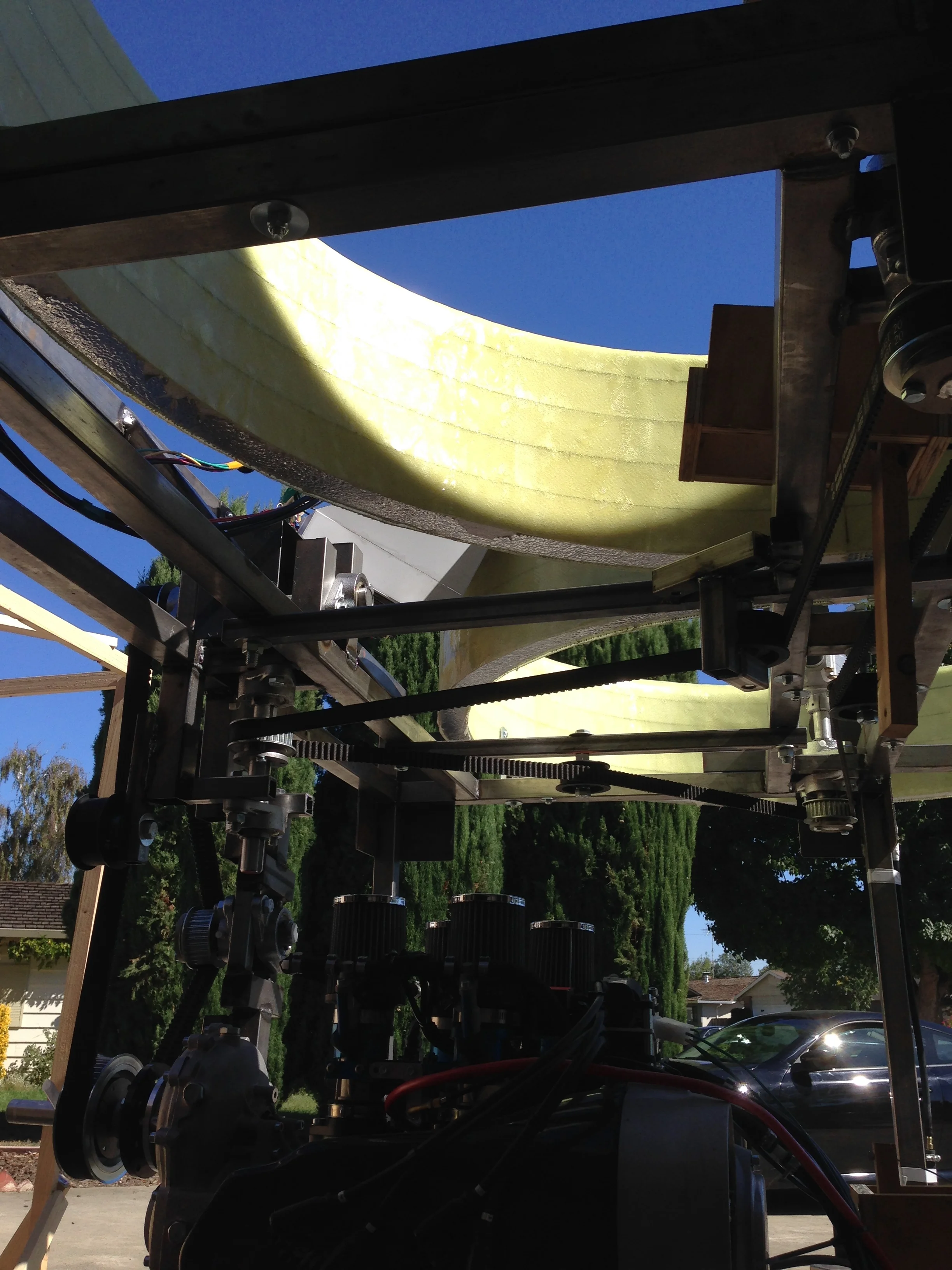

Ever wonder how the bottom of the fiberglass was cut off? This is how!