Almost this entire spool of 1/0 gauge cable was used to move power around the Mark III - roughly 40-45lbs in total

The steel bars for the top portion cut and labeled, ready for welding! In case you're wondering, it's 4130 steel, which is a special grade that's higher strength and lower weight than regular mild steel.

Start of the welding!

This was the CAD mock-up of the Mark III for how it was designed before any metal was bought

The CAD mock-up of the Mark III - top view

The CAD mock-up of the Mark III

String and cardboard was used (very high-tech) to visualize several options for the protective shielding

Testing the chair positioning with string to make sure the pilot's head wouldn't be hitting the back panel

Cutting and drilling the safety panels

Our commitment extends to safety - including eye, ear, and lung protection during construction. Sadly, it's really hot and stuffy when you wear all this.

The back panel was the most complex to build due to the 3D geometry

We tried to use the Thrust Testing Rig to shape and cut the ducts by spinning Styrofoam. All it did was make a mess.

Old ducts from the Mark I and Mark II

The large amperage requirements meant we needed really thick cables to transmit power from the batteries to the motors

The Mark III ducts were made out of carbon fiber, but still a huge pain to build by hand

The final product of the ducts - they look fantastic!

This was the new mold we 3D printed to form the duct core (using an expanding foam)

During duct construction, we tried used ever-increasing amounts of epoxy to be more efficient, until we mixed too much and it got hot enough to melt the cup it was in...

We also tried 3D-printing some wheel adapters to attach it to the frame. They broke the moment someone sat in it.

Prepping for paint!

These were all the wires that were hand-soldered to connect the batteries together

First attempts to mount ducts to the frame

Sometimes the 3D printer didn't want to cooperate on large, overnight prints

Each side had its own controls for power and battery monitoring. Each also required two switches to be pressed to activate power to the motors to ensure they couldn't accidentally be turned on.

Spray painting the duct bars

Spray painting the duct bars

By now the Mark I frame was rusting away and would soon be scrapped

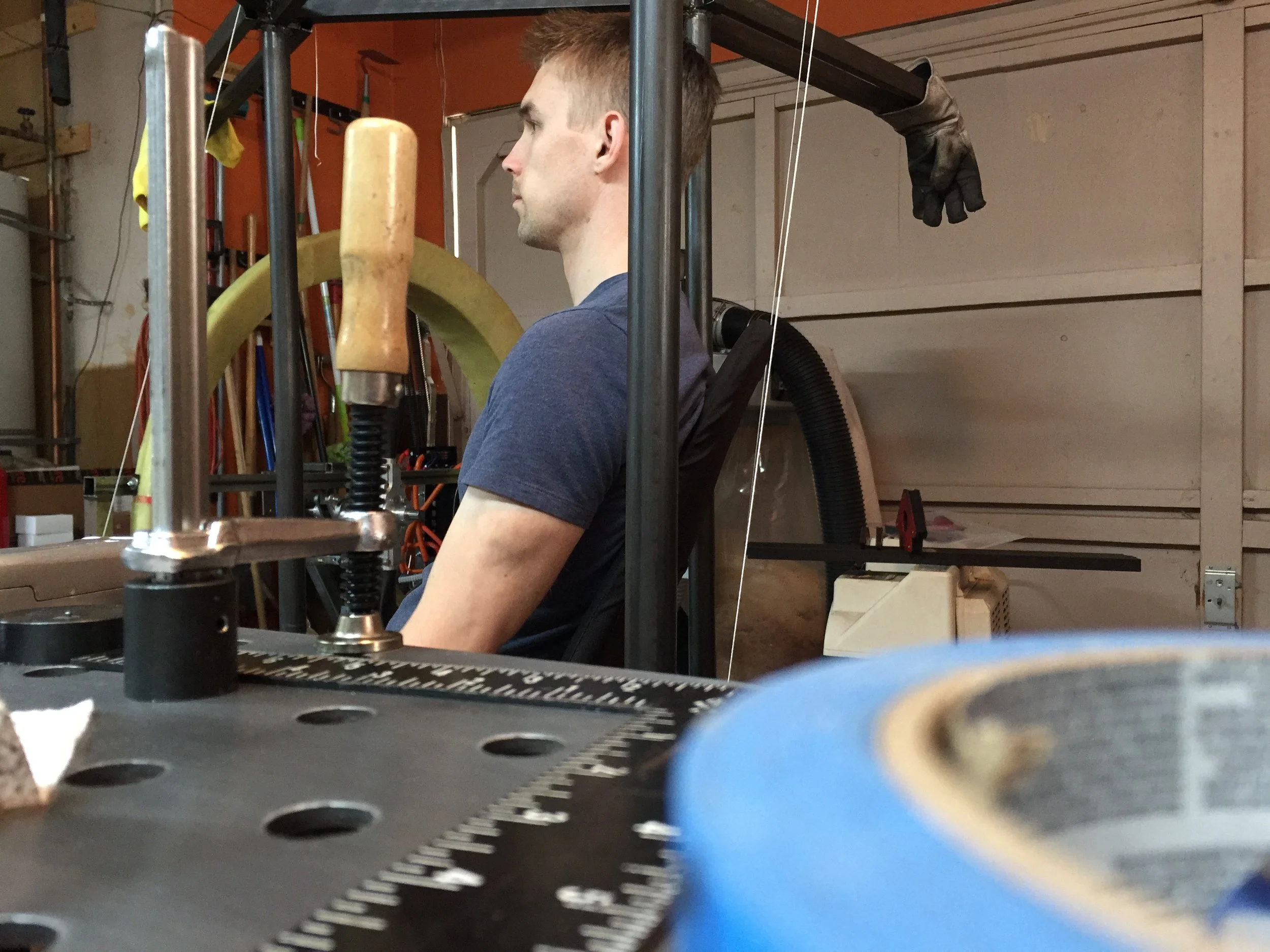

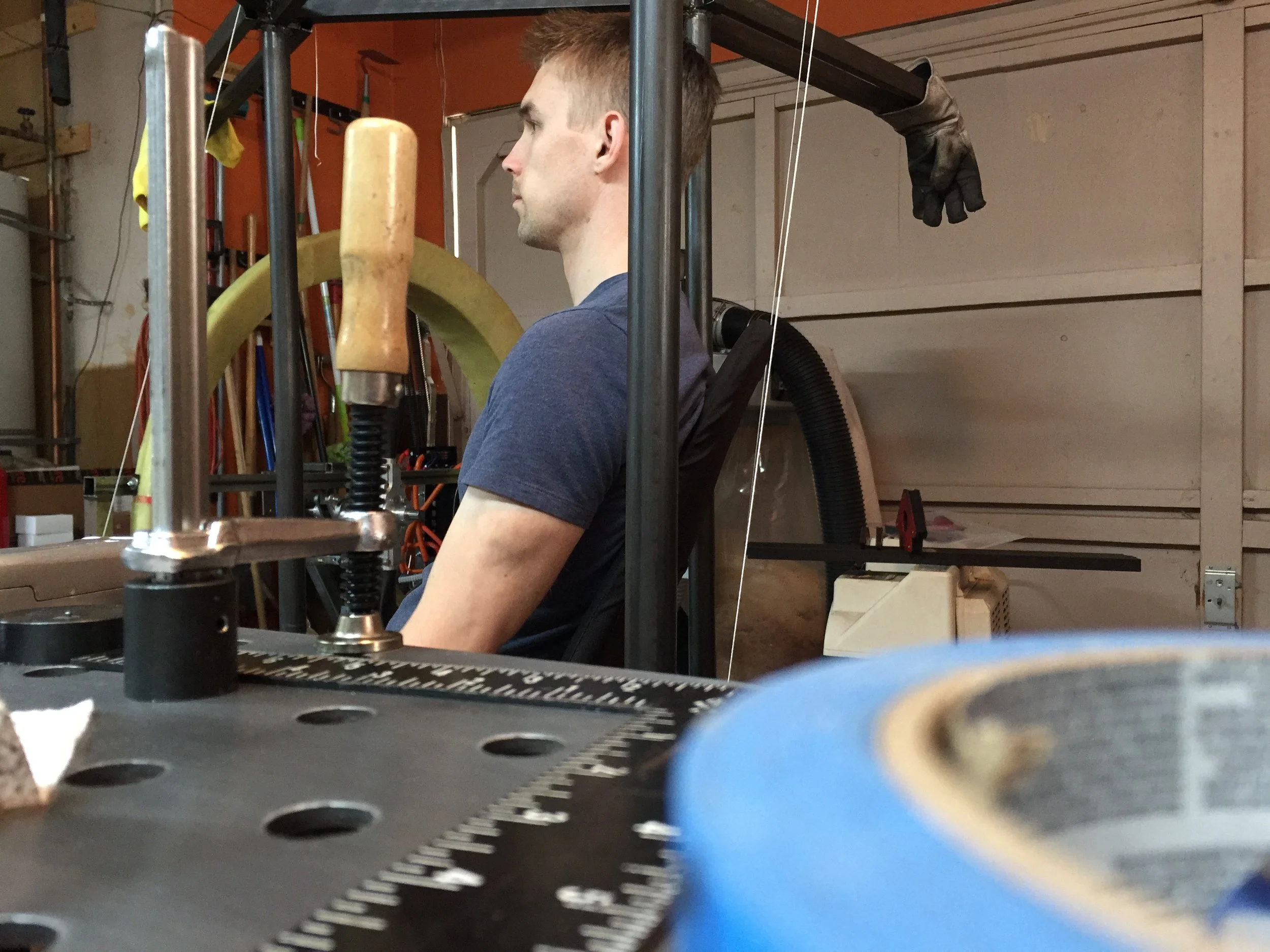

First efforts to hook get the new motors working!

Early concepts for the Mark IV while the Mark III was still under construction

You really have no idea just how difficult the wiring was to make all this work

By the end, all the cables were nicely wrapped up so the mess was hidden

Each motor had an independent power supply of 16 batteries

This is how many batteries it took to power the Mark III - 64 batteries weighing ~100lbs